Building Better

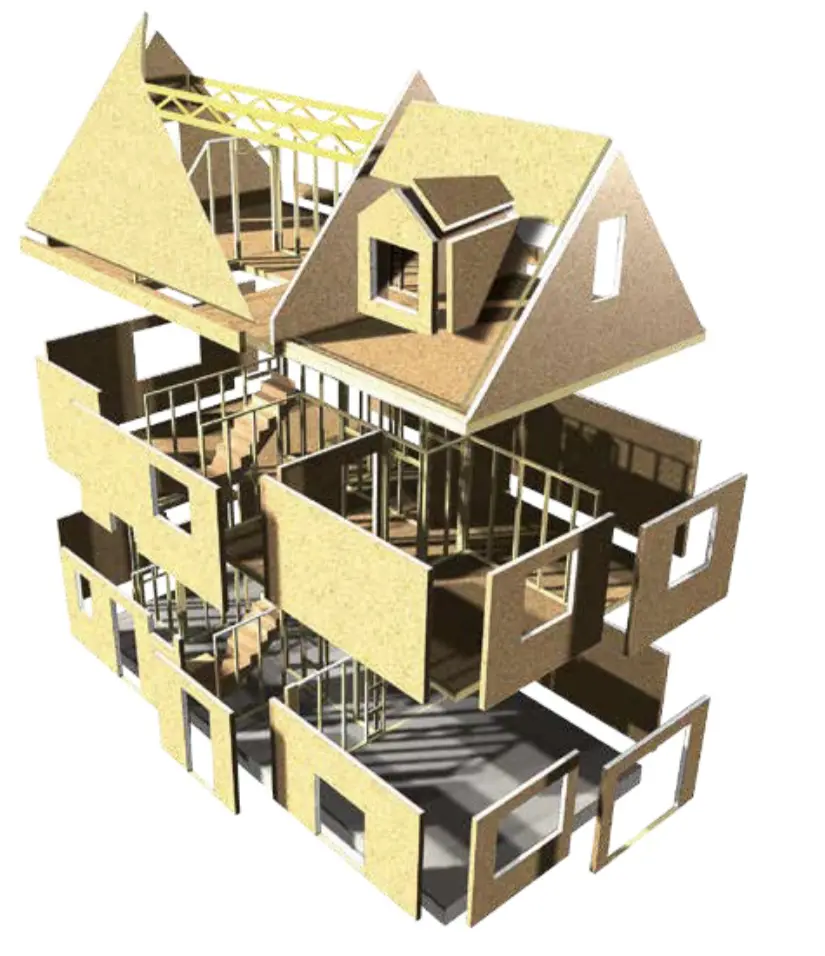

and Smarter With SIPS

Supplying Structural Insulated Panels With Quality Installation Services

SIP Packages Available Across North & Mid-Atlantic Region

At American Structural Insulated Panels Systems, we are the trusted suppliers of Structural Insulated Panels (SIPs) serving across the North/Mid-Atlantic region and beyond. We offer sales, design, and installation services and pride ourselves on delivering high-quality SIP packages tailored to each residential or commercial project's needs.

Get Numerous Benefits

Structural Insulated Panels (SIPs) have become popular in the construction industry due to their numerous benefits. They are a cost-effective and energy-efficient construction system that can save labor, time, and cost. Our SIPs offer superior insulation and air sealing capabilities, which can lead to significant energy savings over time.

Various Applications

Expanded Polystyrene Foam Core

EPS is an inert, stable cellular plastic with superior insulating qualities. Unlike many other foam products, EPS is "ozone-friendly" - no CFCs or HCFCs are used to produce panels. Other characteristics of EPS include:

Exterior and Interior Skins

The oriented strand board skins on structural panels are exterior-rated Exposure I, certified by the American Plywood Association (APA).

Energy Efficiency & Comfort

At American Structural Insulated Panels Systems, we know that Structural Insulated Panels (SIPs) are highly effective in reducing heating and cooling costs. Our SIPs form a solid thermal envelope around the structure, which is uninterrupted by typical studs, sills, or headers, substantially reducing air infiltration compared to conventional construction techniques.

Moreover, the solid insulation core in our SIPs eliminates the convection looping that can occur in gaps and spaces typical in batt insulation. Our SIPs provide even more significant energy savings than the high R-rating suggests.

Strength & Durability

Inspections, Ratings & Reports

At American Structural Insulated Panels Systems, we provide complete transparency and assurance to our clients. All of our research reports and test results are available upon request, giving you full access to the information you need. Furthermore, you can rest assured that all of our structural insulated panels fully comply with applicable building codes and standards, ensuring that your project meets the highest safety and quality standards.

Nailbase Panels (Timber Frame and Retrofit Panels)

Nailbase panels offer a simple and effective way to enhance the energy efficiency of older homes. These composite panels consist of rigid insulating foam bonded to a single sheet of oriented strand board (OSB) structural sheathing. They can be installed over timber frame posts and beams, cut to size on-site, and installed directly over existing wall and roof sheathing for retrofit projects. This provides additional insulation without disturbing the home's interior.

Once installed, new cladding can be attached directly to the OSB face, serving as the fastening surface for siding or roofing. Nailbase panels are an excellent option for homeowners looking to incorporate energy conservation measures into their home renovation projects.

Advantages of Using Nailbase Panels

Insulation Properties

Calculated R-factors are for the composite panel and include two sheets of7/16" OSB at .57 each; EPS at R3.85 per inch at 75 degrees Fahrenheit and R4.35 at 25 degrees Fahrenheit. For more information on R-values, visit the Oak Ridge National Labs website at http:www.ornl.gov/roofs+walls/whole_wall/rvalue.html

Design Services

At American Structural Insulated Panels Systems, our team of designers works closely with you to create a custom SIP design that meets the specific needs of your project. With a deep understanding of SIP construction, our designers seamlessly incorporate SIPs into your construction drawings. We provide preliminary shop drawings for your review, ensuring that all dimensions and details are accurate before final manufacturing and installation. Once approved, the final shop drawings guide the manufacturing and installation process.

HVAC Analysis

Proper ventilation and conditioning are crucial considerations for the high-performance SIP envelope. We recognize the importance of an appropriately sized HVAC system to ensure the long-term durability of your structure and the comfort of its occupants. Our team of professional HVAC designers works to accurately predict energy demands for super energy-efficient SIP structures, preventing high equipment costs and ensuring indoor air quality is addressed correctly. With our analysis, your HVAC contractor will quote what is required for a perfectly sized system, providing optimal comfort and energy efficiency for your structure.

Meeting Your Engineering Needs

At American Structural Insulated Panels Systems, we understand that engineering is crucial to any construction project. That's why we offer comprehensive coordination of the engineering needs for your project. We have established working relationships with professional structural engineers experienced in reviewing SIP projects. While most projects do not require a review by a professional engineer, we always recommend checking with your local official having jurisdiction (OHJ) to ensure compliance with applicable building codes and regulations.

Certified Installers

At American Structural Insulated Panels Systems, we take pride in our installation crews' expertise and experience in the proper methods for installing and sealing high-performance SIP envelopes. We have certified SIP installers who have received extensive training and a thorough understanding of the unique challenges of SIP installation. While our installation crews are primarily located in the North and Mid-Atlantic regions, their reputation for quality workmanship and attention to detail has taken them to jobs around the country and even the globe.

Technical Adviser

American Structural Insulated Panels Systems offers technical advisory services to assist construction crews with SIP installation. Our team of SIP Certified Installers can work alongside your crew for a day, week, or month, providing specialized tools and expertise to fabricate or modify your SIP package. Whether you need help installing a blank panel package or a fully fabricated SIP envelope, our team can ensure your project stays on track and within budget.

Estimate Your Structural Insulated Panel Project

American Structural Insulated Panel Systems offers sales, design, and installation services, specializing in supplying Structural Insulated Panels (SIPs) and providing high-quality installation for residential and commercial projects. We pride ourselves on tailoring SIP packages to meet the specific needs of each project.

Calculate the Total Wall Area:

Accurate measurement of the length and height of each wall is essential to determine the total wall area. Multiply the length and height of each wall to obtain the individual wall area. Sum up the areas of all the walls to calculate the total wall area.

Calculate the Total Roof Area:

Calculate the total roof area by multiplying the diagonal distance times the ridge length and adding all roof areas together.

Wall Area + Roof Area = Total Panel Square Feet:

Please ensure precise measurements for accurate calculations, allowing us to deliver the ideal SIP solutions tailored to your project's specifications.

Our cost estimate formula provides a quick and easy way to calculate a rough estimate during the planning phase of your project. These calculations are based on averages, and individual designs will vary depending on style, location, and panel usage.

This calculation below is based on an average size structure (1,800 - 3,000 sq. ft. of living space). It is important to note that these figures should not be used for additions as project costs can vary significantly due to site location, access, proximity to equipment and lumberyards, time of year, and project complexity.

1. Calculate the total wall area by multiplying the length of the wall times its height and adding all wall groups together.

2. Calculate the total roof area by multiplying the diagonal distance times the ridge length and adding all roof areas together.

3. Wall area + Roof area = Total Panel Square Feet

For the material cost, multiply the total panel area by $15.00(due to volatility in the building materials market, this price can vary based on current commodity pricing).

This calculation provides 4 1/2" wall panels and 8 1/4" roof panels. For thicker panels add $1.00 per square foot for each increase in thickness; for example, 6 1/2" walls and 10 1/4" roofs would be $16.00 per square foot.

This price is only for quick estimating purposes. The cost may be less based on the design of the structure and the optimization of the panel cutting. The panels can be as large as 8ft x 24ft.